Home

/

Installation

/

Snow Melting Mat – WSMM

Installation of Snow Melting Mat/Cable under Asphalt

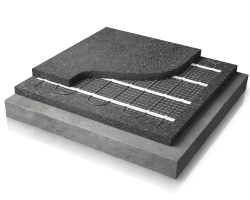

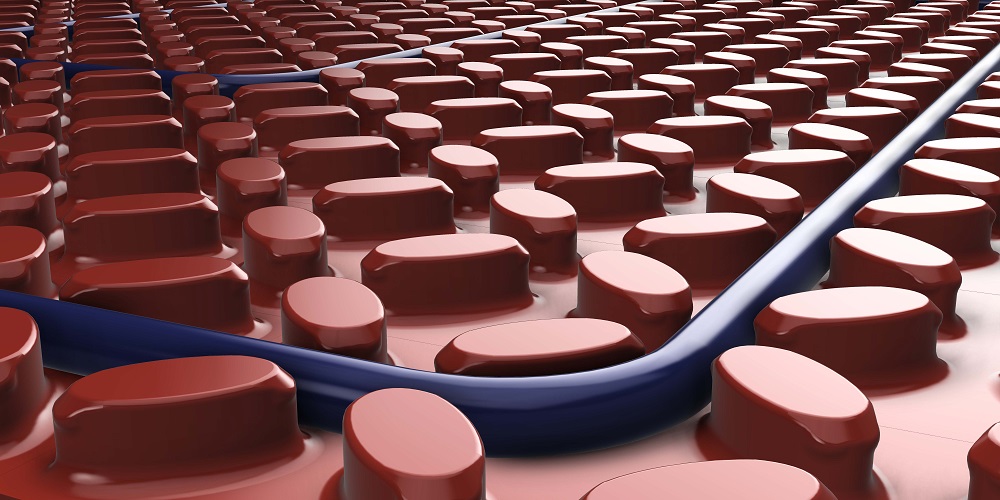

Snow Melting Mats/Cables are uniquely designed for snow melting in parking lots, driveways, pavements, stairs, bridges, roofs, etc. with total safety. Snow melting systems are heating cables taped to a sturdy mesh for fast, easy installation. Snow Melting Mats and Cables consist of a twin conductor heating cable taped onto the Polypropylene mat. The heating cable is laid in a winding fashion so that they are equally spaced (3” apart) and evenly distributed on the mat.

NOTE: INSTALLATION IN ASPHALT

The temperature must not exceed 80 °C or 176 °F around the sensor and tube. Those temperatures are well below the typical asphalt pour temperatures, and we highly recommend the use of our reinforced cables specifically designed for asphalt. Always use METAL conduits for asphalt installations, and install your sensor retroactively. Create a wooden perimeter to protect your sensor location from the pour, and subsequently affix the sensor in the ground, finishing the pour around that section.

Please watch this video for more instruction

Subscribe to our YouTube channel here.

INSTALLATION INSTRUCTIONS – UNDER ASPHALT

We highly recommend the use of our reinforced cable specifically designed for asphalt use. When using the regular snow melt mats/cables under asphalt, consider embedding them in sand or concrete first. Note: Using a megohmmeter and multi-meter, an electrician should measure the cable resistance and insulation resistance:(1) before commencing installation,(2) before applying asphalt and(3) after the asphalt is applied. Record the readings in this manual. If there is damage STOP and ring 1-888-927-6333.

1. Ensure the contractor has a firm base of 4”-8” (102-203mm) of concrete, sand or rock aggregate tamped down and ready to receive the asphalt.

2. Clean the area below the heating mat/cable so that it is free from sharp objects. It is extremely important to keep heavy equipment, machinery, vehicles, shovels and rakes away from the cable to prevent damage. In the application of asphalt, we recommend a maximum load of 2 tons for the roller. To minimize strain on the cable, lay the mats perpendicular to the roller’s path.

3. Lay down the binder/base coat of asphalt and roller it smooth. The paving installer must decide if the binder coat of asphalt is allowed to cool before proceeding.

4. Unroll the mat or place the cable on the prepared surface (wires facing down, mesh-side facing up to help protect the wire) according to your layout plan and apply a coat of bituminous binder. See pg 10 “How to Modify the Mat” if you need to alter the mats (Note: test the mats/cables to ensure they have not been damaged and record the readings).

5. Once the mats/cables are in place, route the cold lead(s) provided through a rigid metal conduit to return to an accessible weatherproof junction box(es). The electrician may supply junction boxes which can be accessed from above so the rest of the box is buried to avoid damage by vehicles or lawn movers. [Note: ensure none of the heated section of the cable enters the conduit(s)]. Seal the ends of the conduit.

6. Sensors can be placed within the asphalted area. Refer to earlier sections under PLACING GROUND SENSORS on page 3.

7. When the mat/cable is embedded in sand or mortar, the asphalt should not exceed a thickness of more than 1.5” for optimal results. When pouring asphalt DIRECTLY on the mat/cable, let it cool to 230F and below. Again, use a maximum of 2” of asphalt for optimal results.

8. After the asphalt hardens, test and record results to verify that there is no damage and to ensure it is ready for activation once the asphalt has cured.

9. For easy reference, attach a label at the power distribution board, indicating the location of the heating cables.

Please refer to the installation manual for more information regarding the installation of this product.

![Thumbnail [200x250]](/wp-content/uploads/Indoor-Systems-Page-Image.png)

![Thumbnail [200x250]](/wp-content/uploads/image-13.png)

![Thumbnail [200x250]](/wp-content/uploads/Projects-Image.png)