When installing flooring – especially over a radiant floor heating system – choosing the right type of thinset is crucial in ensuring its long-term condition. Although very similar in name and application, modified and unmodified thinsets differ in critical ways so, in this expert guide, we’ll walk you through the key differences. You’ll learn more about:

- What is thinset mortar?

- The key differences between modified and unmodified thinsets

- Which type of thinset is best to use for floor heating installations

- Our top tips for mixing thinset

What is Thinset Mortar?

Thinset mortar is a type of adhesive that bonds floor tiling and other floor finishes to a property’s substrate. As a strong, cement-like material, it facilitates the use of only a very thin bed – thus, the name thinset.

Unmodified vs. Modified Thinsets

Unmodified thinset is composed of three main ingredients; portland cement, sand, and powdered water retention additives. Unmodified thinset is sold as a dry powder mixture in a bag and can be found in the tile section of just about any home improvement or hardware store.

Modified thinset has the same essential elements as its unmodified counterpart but includes latex/polymer additives. The additives increase adhesion, strength, and shock resistance while also reducing water absorption. Modified thinset is available as a powdered mixture in most, if not all, home improvement stores. Pre-mixed products are also sometimes available in sealed buckets.

What Kind of Application is Unmodified Thinset Mortar Best For?

Traditionally, unmodified thinset mortar has been used to adhere an impervious tile to an impermeable backing: for example, installing floor tiles onto a concrete substrate or an impervious flooring membrane. It offers low flexibility levels and needs both time and moisture to cure. Most tile manufacturers will specify which type of thinset to use with their products and it’s vital to follow these directions for a successful tile installation.

When is it Preferrable to Use Modified Thinset Mortar?

Because of modified thinset’s latex/polymer additives, you can use it to adhere tiles to more porous materials (which can suck the moisture out of unmodified thinset) such as a plywood subfloor. The additives create a robust and sticky bond between the flooring and subfloor, enhancing flexibility and strength whilst also offering a quicker, dryer curing process. The many advantages of modified thinset makes it the preferred product for most floor tiling installation projects.

Want to find out more about the differences between ceramic and porcelain floor tiles? Read our in-depth guide.

What Type of Thinset Should I Use When Installing Radiant Floor Heating?

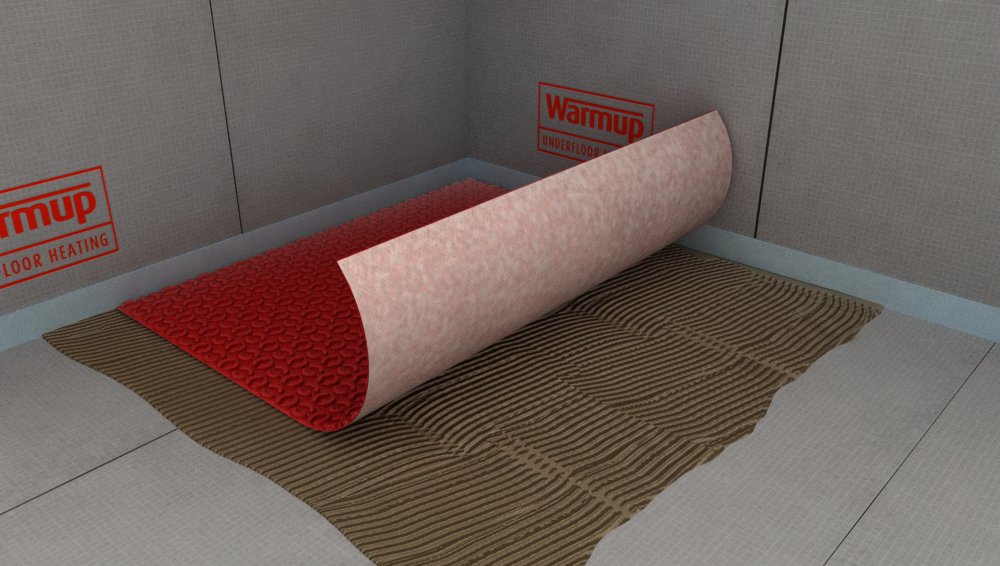

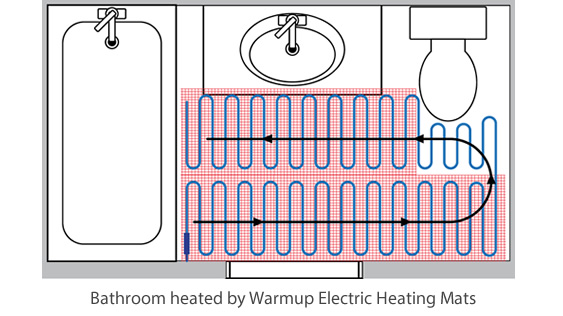

Warmup recommends using modified thinset for our collection of electric floor heating systems because of its increased flexibility and strength. Different heating systems require different installation methods when it comes to thinset application, however.

The StickyMat features an innovative self-adhesive backing which eliminates the need for thinset below the system – just requiring a thin layer to cover the system with which to adhere the flooring.

As a membrane and heating cable combination UFH solution, the DCM-PRO Heated Uncoupling System offers two membrane options: one which requires the use of thinset below the system and another which does not.

The Foil Heater meanwhile, allows for a ‘dry’ installation – meaning thinset is not required to either adhere the system to the substrate or to install the floor covering above it.

It’s worth nothing that you must allow the thinset to fully cure before turning on the radiant floor heating. Powering the system before the thinset has fully cured could cause the thinset to become brittle, potentially damaging the heating system.

5 Top Tips for Mixing Thinset

When mixing thinset, regardless of whether it is modified or unmodified, there are a few essential techniques that will help ensure its performance.

1. Add the powder to the water, not the other way around.

Pour water into your bucket and then pour in your powdered thinset mix. By starting with water, you won’t have dry, unmixed thinset on the bottom of your bucket.

2. Make small batches; don’t try to mix the whole bag all at once.

Thinset mortar has a finite amount of working time, so it’s a good idea that you have the ability to make minor adjustments to your mix as you go. Is your mix looking a little dry? No problem, add a little more water. Is your mix looking too wet? Sprinkle in a little more thinset. If you start with the whole bag of thinset and your mixture is too wet, you have nothing left to add to it.

3. Use a mechanical mixer.

You can mix thinset by hand, but it is substantially more work and will inevitably yield worse results than a mechanical mixer. Buy a mixing paddle attachment for your drill; they are relatively cheap (about $12) and will make your life significantly easier.

4. Run a trowel through your thinset to test the consistency.

You want your mixed thinset mortar to have the consistency of cake frosting: it should hold its ridges and have a light, whipped feel.

5. Wear protective equipment when you are mixing thinset.

Thinset contains silica dust. Inhaling silica dust is bad for your lungs, and long-term exposure can result in silicosis, so it’s very important that you wear a mask or respirator when mixing thinset. Thinset also contains lime, which can burn and irritate your eyes if it splashes up into your face. Be sure to wear eye protection and rubber gloves too.

Where Can I Find More Support for My Floor Heating Installation Project?

Looking for more information about using thinset with a radiant floor heating system? Find out everything you need to know on Warmupedia, our renowned online support center. By following our expert advice, you can rest assured that your upcoming installation will go smoothly.

You can also get instant pricing for a new Warmup system by using our online quoting tool. Enter a few basic details of your project and we’ll show you the best solution for your needs, how much it will cost to buy and where to purchase it.

![Thumbnail [200x250]](/wp-content/uploads/Indoor-Systems-Page-Image.png)

![Thumbnail [200x250]](/wp-content/uploads/image-13.png)

![Thumbnail [200x250]](/wp-content/uploads/Projects-Image.png)